Printing Envelopes & Flatwork: Ink On Paper

Katherine Gouldin

Brand Communications Associate

Sherri Raines

Senior Account ManagerTo serve our client’s needs, Production Solutions (PS) focuses on the impact our client wants to make with their mailing, the intention behind it, and the quantity of the project using our wide network of supplier partner relationships. Let’s learn about the specifics of printing and how PS adds value to your work through our knowledge of ink on paper!

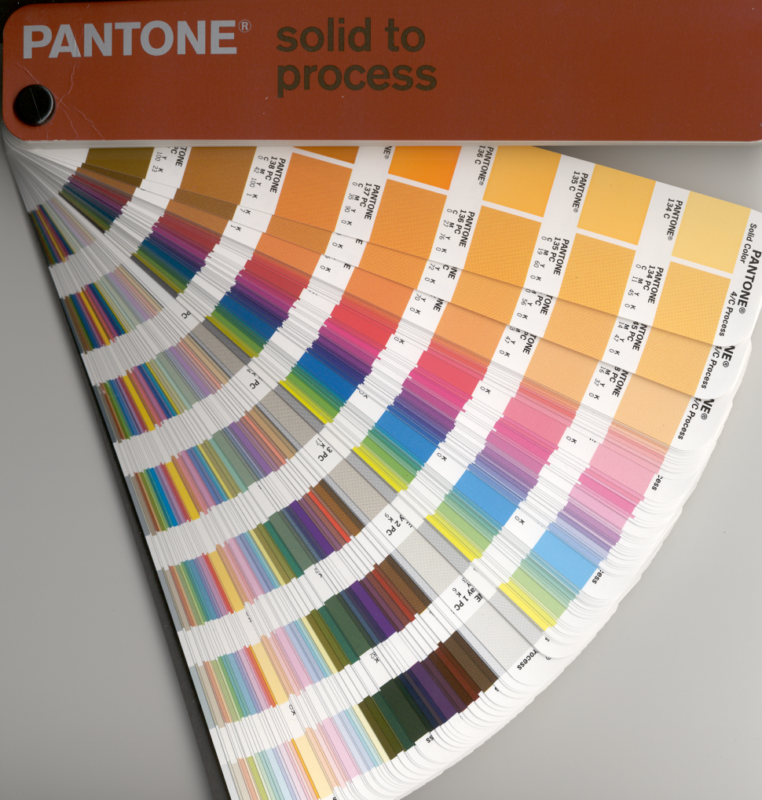

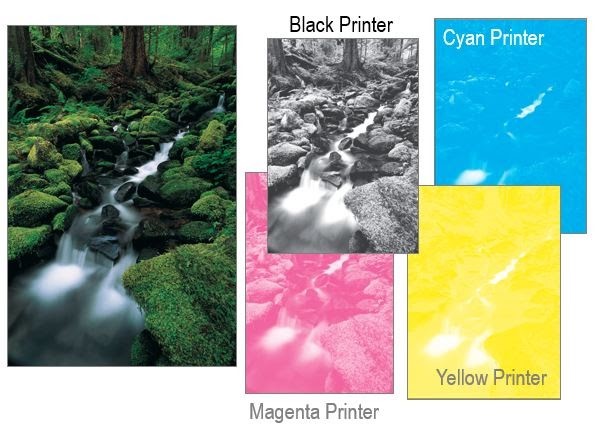

There are 2 ways to print color images and text: using PMS (Pantone matching system) color printing or 4color process (4cp) printing. PMS ink is premixed and ordered from an ink supplier (much like buying paint for your house at a store). 4cp is achieved by laying down 4 colors: cyan, magenta, yellow, and black, and it is used for pictures and full-color images. While it is possible to replicate some PMS colors with a 4 color build, not all colors can be built to match a PMS color. This is important to note especially when you are printing some items in a 4 color build and some items in the same mail piece with a PMS color.

For example, if a client wants to print their logo on the carrier with 2PMS colors and then use a 4 color build for the logo on the letter/reply, depending on the color, the two may not be a perfect match. This difference in the ink color method can lead to two very different logo colors. In order to prevent issues from arising with similar but different ink colors, your production expert will communicate with you (the client) very early on to let you know about color differences in different types of printing.

Envelopes

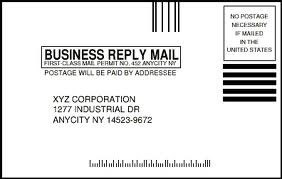

The most common methods for printing envelopes are: Flexography (Flexo), Jet Litho, and Flat Sheet Litho printing. Flexo Printing is the method when a large roll of paper is fed into the press- the printing impression is made (much like a rubber stamp image), gum is applied, then it’s converted into an envelope all in one pass where an operator retrieves them at the end and loads them into a box. Flexo printing is often used for simpler art (such as reply envelopes) and can be a very cost-effective way to print larger volumes of envelopes that don’t require intricate printing.

The most common methods for printing envelopes are: Flexography (Flexo), Jet Litho, and Flat Sheet Litho printing. Flexo Printing is the method when a large roll of paper is fed into the press- the printing impression is made (much like a rubber stamp image), gum is applied, then it’s converted into an envelope all in one pass where an operator retrieves them at the end and loads them into a box. Flexo printing is often used for simpler art (such as reply envelopes) and can be a very cost-effective way to print larger volumes of envelopes that don’t require intricate printing.

Jet Litho Printing requires two processes. First, the supplier either creates the envelope or buys the envelope already assembled (much like you would buy them at the office supply store), then the envelope is fed through a press and the ink is applied. The quality of the print is higher than the flexo option. There are however limitations to how many colors you can print and the printing can not bleed off the page. Jet litho printing is cost-effective for small print runs as these small presses are easy to set up.

Jet Litho Printing requires two processes. First, the supplier either creates the envelope or buys the envelope already assembled (much like you would buy them at the office supply store), then the envelope is fed through a press and the ink is applied. The quality of the print is higher than the flexo option. There are however limitations to how many colors you can print and the printing can not bleed off the page. Jet litho printing is cost-effective for small print runs as these small presses are easy to set up.

Flat Sheet Litho Printing is the third and most often the most expensive option for printing envelopes. This requires three processes and is the highest-quality printing option. In this method, flat sheets of paper are fed into a printing press, then the printed sheets are die cut, then folded, gummed, and converted into envelopes. Flat sheet litho is often used for 4cp printing, sophisticated art, and components with heavy ink-coverage and bleeds.

Flat Sheet Litho Printing is the third and most often the most expensive option for printing envelopes. This requires three processes and is the highest-quality printing option. In this method, flat sheets of paper are fed into a printing press, then the printed sheets are die cut, then folded, gummed, and converted into envelopes. Flat sheet litho is often used for 4cp printing, sophisticated art, and components with heavy ink-coverage and bleeds.

Flatwork Print Components

In terms of printing the content that goes inside of the envelopes such as letters, replies, and inserts (flatwork), there are 2 methods of conventional lithographic printing and there are also digital options available.

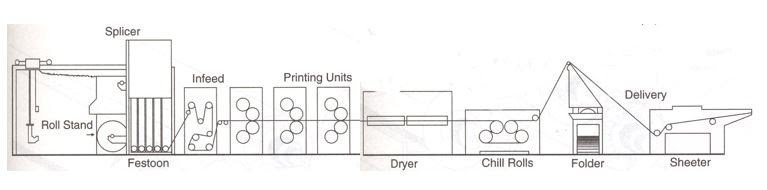

The first is Web Printing which starts with a roll of paper that is pulled through the press and is printed with any non-personalized information. Web presses are large and require a lot of set-up time (make-ready), therefore it is not ideal for low quantities, but once running they have very high throughput so this method is ideal for large quantities. Paper choices are somewhat limited because not all paper types are available in web rolls.

The first is Web Printing which starts with a roll of paper that is pulled through the press and is printed with any non-personalized information. Web presses are large and require a lot of set-up time (make-ready), therefore it is not ideal for low quantities, but once running they have very high throughput so this method is ideal for large quantities. Paper choices are somewhat limited because not all paper types are available in web rolls.

Sheetfed Printing is the method where individual sheets of paper are fed one by one through the press (as opposed to a roll). This is the same process used to print the Flat Sheet Litho envelopes listed above and there are almost no limitations when it comes to the ability to print art — if the print quality is of the utmost importance – sheetfed printing is likely the way to go. In addition, paper options are almost limitless with this type of printing. Sheetfed presses are much smaller than web presses and therefore have quicker make-ready times making them cost-effective for small quantities; however, throughput is much slower making them a more expensive option for higher volume projects.

Sheetfed Printing is the method where individual sheets of paper are fed one by one through the press (as opposed to a roll). This is the same process used to print the Flat Sheet Litho envelopes listed above and there are almost no limitations when it comes to the ability to print art — if the print quality is of the utmost importance – sheetfed printing is likely the way to go. In addition, paper options are almost limitless with this type of printing. Sheetfed presses are much smaller than web presses and therefore have quicker make-ready times making them cost-effective for small quantities; however, throughput is much slower making them a more expensive option for higher volume projects.

Digital Printing is also becoming a common option for printing, just like conventional printing these presses come in web and sheetfed forms. Digital presses work much like an extremely sophisticated version of a home printer. This type of printing is great for small quantities and can also handle variable data printing (VDP) where you can change full-color images and have fully variable personalization with each piece that is printed.

Digital Printing is also becoming a common option for printing, just like conventional printing these presses come in web and sheetfed forms. Digital presses work much like an extremely sophisticated version of a home printer. This type of printing is great for small quantities and can also handle variable data printing (VDP) where you can change full-color images and have fully variable personalization with each piece that is printed.

Suppliers have a wide variety of print capabilities available, therefore it is crucial to have a production expert as a partner to communicate your goals and choose suppliers who have the appropriate capabilities and equipment to achieve them. PS is able to communicate with our supplier partners about what their niche is and what will work best for your campaign with all of your expectations and needs considered. Your Account Manager will be in constant communication with the supplier partner and will relay all information necessary to meet the client’s expectations. Working with PS is invaluable because not only does PS have the knowledge about the different printing methods and what will best fit your expectations, but we also have the background to bring light to possible problems earlier in the process and offer solutions that the client would not otherwise be aware of.

About the Author

Katherine Gouldin

Brand Communications Associate